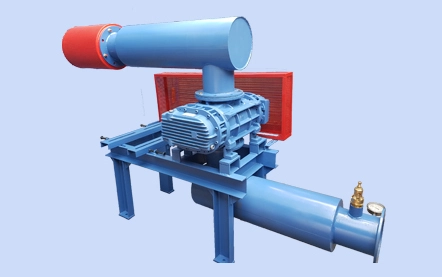

Tri Lobe air blower

Tri Lobe Air Blower Supplier & Manufacturer in India

Airvac Industries is a distinguished name in the blower manufacturing sector, known for its commitment to quality and innovation. As a prominent tri lobe blower manufacturer, Airvac Industries specialises in producing blowers that offer enhanced performance and reliability. Tri lobe blowers deliver a consistent airflow, making them ideal for applications such as pneumatic conveying and industrial processes.

In addition to tri lobe technology, Airvac is also recognised as a reputable lobe air blower manufacturer. This specialisation allows the company to provide a range of blowers that cater to different industrial needs. Lobe air blowers are renowned for their efficiency and minimal maintenance needs, making them suitable for a wide range of applications.

We place a strong emphasis on engineering excellence and customer satisfaction. Our products undergo rigorous testing to ensure they meet industry standards and perform optimally in demanding conditions. Our dedication to innovation helps us stay ahead in a competitive market, continually enhancing our offerings to meet evolving client demands.

Description

Embark on a transformative journey with Airvac’s groundbreaking Tri-Lobe Blower, a result of

cutting-edge technology and design adaptation. With a capacity range of 100 m³/hr to 15,000 m³/hr at a working pressure of 1 kg/cm², it guarantees 100% oil-free air delivery. The Tri-Lobe configuration, featuring a 120-degree tip arrangement instead of the conventional 180 degrees, ensures a stiffer rotor that resists deflection under load. This unique design elevates volumetric efficiency, reduces operating temperatures, and minimises vibrations and noise—ideal for diverse applications.

Features

- Leak-proof sealing arrangement for 100% oil-free applications

- Factory engineered, factory guaranteed, superior product

- Precision case-hardened and ground helical gears for smooth, quieter operation

- Anti-friction bearings

- All rotating parts dynamically balanced for smooth running before bearing assembly

- Rugged construction for heavy-duty applications

- Rotary oil sealings

- Rigid one-piece CI casing and side plates

- Split casing design for easy maintenance and repair

- High efficiency with lower power consumption

- Horizontal and vertical configurations available

- Easy rotor timing setting

- No vanes, valves, or rings to wear

- Large inlet and outlet connections for minimum loss

- Improved volumetric efficiency and reduced operating temperatures

- Alloy steel toughened shafts, ground to close tolerances

Accessories

Standard Accessories

- Common Motor & Compressor base frame with Motor base plate and belt tightening arrangement

- Suction Silencer (M.S)

- Discharge Silencer (M.S)

- Suction Air Filter (Dry Bag Type)

- Pressure Gauge

- Pressure Relief Valve (Spring Loaded Type)

- V-Belts and V-Belt Guard

- Non-Return Valve

- Foundation bolts

- Lubrication Oil

- Set of Drive & Driven Pulleys

- Interconnecting line with flanges

- Operation & Maintenance Manual

Optional Accessories

- Electric Motor

- SS Expansion Bellows

Description

Embark on a transformative journey with Airvac’s groundbreaking Tri-Lobe Blower, a result of

cutting-edge technology and design adaptation. With a capacity range of 100 m³/hr to 15,000 m³/hr at a working pressure of 1 kg/cm², it guarantees 100% oil-free air delivery. The Tri-Lobe configuration, featuring a 120-degree tip arrangement instead of the conventional 180 degrees, ensures a stiffer rotor that resists deflection under load. This unique design elevates volumetric efficiency, reduces operating temperatures, and minimises vibrations and noise—ideal for diverse applications.

Features

- Leak-proof sealing arrangement for 100% oil-free applications

- Factory engineered, factory guaranteed, superior product

- Precision case-hardened and ground helical gears for smooth, quieter operation

- Anti-friction bearings

- All rotating parts dynamically balanced for smooth running before bearing assembly

- Rugged construction for heavy-duty applications

- Rotary oil sealings

- Rigid one-piece CI casing and side plates

- Split casing design for easy maintenance and repair

- High efficiency with lower power consumption

- Horizontal and vertical configurations available

- Easy rotor timing setting

- No vanes, valves, or rings to wear

- Large inlet and outlet connections for minimum loss

- Improved volumetric efficiency and reduced operating temperatures

- Alloy steel toughened shafts, ground to close tolerances

Accessories

Standard Accessories

- Common Motor & Compressor base frame with Motor base plate and belt tightening arrangement

- Suction Silencer (M.S)

- Discharge Silencer (M.S)

- Suction Air Filter (Dry Bag Type)

- Pressure Gauge

- Pressure Relief Valve (Spring Loaded Type)

- V-Belts and V-Belt Guard

- Non-Return Valve

- Foundation bolts

- Lubrication Oil

- Set of Drive & Driven Pulleys

- Interconnecting line with flanges

- Operation & Maintenance Manual

Optional Accessories

- Electric Motor

- SS Expansion Bellows

Features

- Leak-proof sealing arrangement for 100% oil-free applications

- Factory engineered, factory guaranteed, superior product

- Precision case-hardened and ground helical gears for smooth, quieter operation

- Anti-friction bearings

- All rotating parts dynamically balanced for smooth running before bearing assembly

- Rugged construction for heavy-duty applications

- Rotary oil sealings

- Rigid one-piece CI casing and side plates

- Split casing design for easy maintenance and repair

- High efficiency with lower power consumption

- Horizontal and vertical configurations available

- Easy rotor timing setting

- No vanes, valves, or rings to wear

- Large inlet and outlet connections for minimum loss

- Improved volumetric efficiency and reduced operating temperatures

- Alloy steel toughened shafts, ground to close tolerances

Accessories

Standard Accessories

Standard Accessories

- Common Motor & Compressor base frame with Motor base plate and belt tightening arrangement

- Suction Silencer (M.S)

- Discharge Silencer (M.S)

- Suction Air Filter (Dry Bag Type)

- Pressure Gauge

- Pressure Relief Valve (Spring Loaded Type)

- V-Belts and V-Belt Guard

- Non-Return Valve

- Foundation bolts

- Lubrication Oil

- Set of Drive & Driven Pulleys

- Interconnecting line with flanges

- Operation & Maintenance Manual